In the fast-evolving landscape of industrial automation, maintaining the reliability of pneumatic systems is critical to minimizing downtime and maximizing productivity. Among the most trusted solutions for valve maintenance, ASCO C113928 kits emerge as a cornerstone for engineers and plant managers seeking to extend the lifespan of their pulse jet valves. This article explores the technical specifications, applications, and strategic advantages of these kits, while offering actionable insights for seamless integration into industrial workflows.

What Are ASCO C113928 Kits?

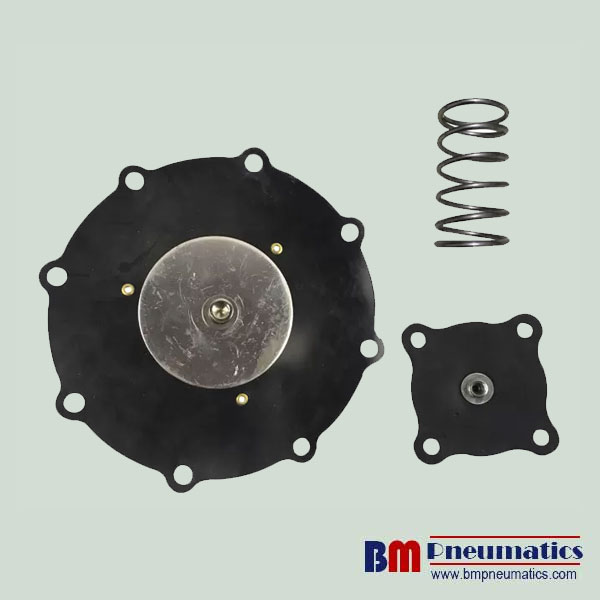

The ASCO C113928 kit is a specialized diaphragm repair solution designed for 3-inch pulse jet valves, including the SCXE353.060 series. Engineered with precision, each kit includes a nitrile butadiene rubber (NBR) diaphragm, a stainless-steel spring, and a stainless-steel backing disk—components crucial for restoring valve functionality in demanding environments. These kits are compatible with multiple valve brands, including Mecair, Norgren, and Goyen, making them a versatile choice for mixed-vendor systems.

Key features include:

- Durability: NBR diaphragms resist chemical degradation and temperature fluctuations, ensuring longevity in harsh conditions.

- Precision Fit: Customized designs eliminate leaks and ensure optimal airflow control.

- Global Availability: Fast shipping via FedEx, DHL, or UPS guarantees delivery within 6–8 days, reducing maintenance delays.

Why Are These Kits Critical for Industrial Operations?

Pulse jet valves are the backbone of dust collection systems, reverse air filtration, and material handling processes. Over time, diaphragms degrade due to cyclic stress, chemical exposure, or abrasive particles, leading to leaks, pressure drops, and system failures. The ASCO C113928 kit addresses these issues by providing OEM-grade replacement parts that restore valves to their original performance specifications.

Case in Point: A leading cement manufacturer reduced unplanned downtime by 40% after adopting ASCO kits for their baghouse filtration systems. The kits’ robust design withstood abrasive particulate matter, outlasting generic alternatives by 18 months in field tests.

Applications Across Industries

The versatility of ASCO C113928 kits extends to multiple sectors:

- Metal Fabrication: Maintaining consistent airflow in plasma cutting and welding systems.

- Pharmaceuticals: Ensuring sterile environments through reliable valve operation in HVAC systems.

- Food Processing: Resisting oil and grease buildup in pneumatic conveying systems.

- Power Generation: Optimizing filter cleaning in coal-fired and biomass plants.

Installation Best Practices

Proper installation maximizes kit lifespan and performance:

- Pre-Inspection: Check for debris in the valve body to prevent diaphragm punctures.

- Torque Specifications: Use a calibrated torque wrench to avoid over-tightening screws.

- Post-Installation Testing: Conduct a pressure decay test to verify seal integrity.

Pro Tip: Pair the ASCO C113928 kit with a preventive maintenance schedule to replace diaphragms proactively, avoiding costly emergency repairs.

Market Trends Driving Adoption

As of 2025, the global diaphragm valve market is projected to reach $2.1 billion, fueled by:

- Industry 4.0 Integration: Smart factories demand valves with IoT-compatible diagnostics, a feature supported by ASCO’s compatible valve models.

- Sustainability Mandates: Energy-efficient valves reduce compressed air consumption, aligning with net-zero goals.

- Supply Chain Resilience: Localized warehousing by distributors like BMPneumatics ensures inventory availability during global logistics disruptions.

Conclusion: A Strategic Investment in Reliability

The ASCO C113928 kit is more than a repair component—it’s a catalyst for operational excellence. By prioritizing quality, compatibility, and timely maintenance, industries can achieve measurable gains in uptime, safety, and cost efficiency.

More info about ASCO C113928 Kits, please visit our official website: www.bmpneumatics.com